North Vancouver, B.C., October 1, 2024 - Lion One Metals Limited (TSX-V: LIO) (OTCQX: LOMLF) (“Lion One” or the “Company”) is pleased to report significant new high-grade gold results from near-mine exploration and infill drilling at the West Zone target west of to the Tuvatu Gold Mine in Fiji. The company is also pleased to report record preliminary Q1 FY2025 gold production at Tuvatu.

Highlights of West Zone exploration and infill drilling:

- 105.20 g/t Au over 2.1 m (including 248.35 g/t Au over 0.3 m) (TUDDH-636, from 67.8 m depth)

- 70.07 g/t Au over 2.1 m (including 73.43 g/t Au over 1.2 m) (TUDDH-647, from 144.5 m depth)

- 102.38 g/t Au over 1.2 m (TUDDH-645, from 97.7 m depth)

- 19.82 g/t Au over 5.1 m (including 68.88 g/t Au over 0.9 m) (TUDDH-636, from 34.5 m depth)

- 146.61 g/t Au over 0.6 m (including 289.85 g/t Au over 0.3 m) (TUDDH-645, from 164.3 m depth)

- 24.16 g/t Au over 3.3 m (including 96.78 g/t Au over 0.3 m) (TUDDH-652, from 173.5 m depth)

- 49.72 g/t Au over 0.8 m (including 78.61 g/t Au over 0.4 m) (TUDDH-755, from 52.94 m depth)

- 42.44 g/t Au over 1.8 m (including 61.66 g/t Au over 0.6 m) (TUDDH-636, from 60.6 m depth)

- 7.68 g/t Au over 4.2 m (including 28.63 g/t Au over 0.3 m) (TUDDH-645, from 142.4 m depth)

- 14.86 g/t Au over 2.0 m (TUDDH-636, from 228.8 m depth)

*All drill intersects are downhole lengths, 3.0 g/t cutoff. See Table 1 for additional data

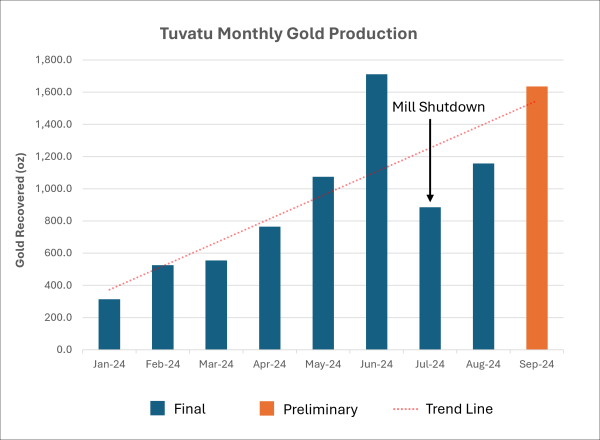

Highlights of quarterly gold production (preliminary results):

- 3,680 oz of gold recovered from July-September 2024

- 31,390 tonnes milled from July-September 2024

- Record quarterly gold production (previous record set in the prior quarter, April-June 2024)

- July production impacted by scheduled 9-day mill maintenance shutdown

- August production impacted by mining equipment breakdown

Quarterly Production Results

Lion One Metals will produce approximately 3,680 oz of gold during the three-month period ending September 30th, 2024. This is a new quarterly production record, beating the previous production record of 3,551 oz of gold produced in the prior three-month period ending June 30th, 2024. Production during the period was impacted by a scheduled 9-day mill maintenance shutdown in July, as well as by mining equipment breakdowns in August. The total tonnes processed during the three-month period ending September 30th was 31,390 tonnes, which is comparable to the prior three-month period of 32,100 tonnes processed.

The mill shutdown in July was conducted to maintain and upgrade the Tuvatu processing plant facilities, and will have a significant impact on processing efficiency and cost savings moving forward. Major upgrades completed during the shutdown include re-lining the primary ball mill with rubber liners, replacing the bowl/mantle for the cone crusher, replacing the #1 conveyor belt, replacing the grinding and gravity circuit piping with flexible slurry hoses, and installing new detox feed pumps and feed splitter box for the detox circuit.

Re-lining the ball mill with rubber liners is a significant upgrade as the lighter weight rubber liners will reduce power draw by the primary ball mill and will enable a higher ball charge and finer primary grind, thereby improving mill recovery and efficiency. Wear life on the rubber liners is also expected to double from 6 months to 1 year thereby reducing long-term maintenance costs. The grinding and gravity circuit piping replacements will improve mill availability and will further reduce maintenance costs as the use of flexible slurry hoses will result in significantly less downtime for pipe repairs than with the previous steel piping. Overall, the upgrades completed during the July mill shutdown have helped to increase mill availability from 89% in the three-month period ending June 30th, to 93% in the three-month period ending September 30th. The upgrades have also helped to increase average daily mill throughput per operating day (excluding the planned mill shutdown) from 353 TPD in the three-month period ending June 30th to 371 TPD in the three-month period ending September 30th. In addition to the processing plant improvements, operational costs from the filtered tailings haulage have also been reduced by bringing the haulage operation in-house with three new trucks acquired during the quarter, which will lead to significant cost savings from operations.

Gold production during the quarter was also impacted by mine equipment availability in August. Two underground loaders were down for repairs simultaneously. Having both loaders down for repairs significantly impacted mining operations as production material could not be extracted from the mine. Stockpiled low-grade development material was therefore fed through the mill during the interim period while the loaders were repaired, resulting in decreased production in August. A new underground loader from Australia was purchased and arrived on site in September resulting in improved equipment availability and enhanced redundancy.

Figure 1. Tuvatu Monthly Gold Production. Gold recovery and production has increased steadily at Tuvatu as mining and processing activities have ramped up during the pilot plant phase of operations. Production was reduced in July due to a scheduled 9-day mill maintenance shut down and was hampered in August due to mining equipment breakdown.

West Zone Drilling

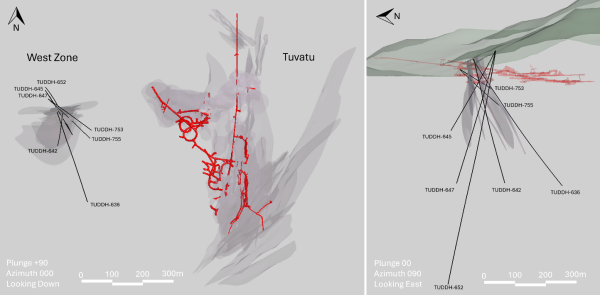

The West Zone drilling consists of two separate programs: a deep exploratory drill program targeting a feeder zone at depth below the West Zone, and a shallow infill drill program targeting near-surface mineralization for inclusion in the Tuvatu mine plan (Figure 2). The deep exploration drill holes are the first holes ever designed to test the depth extension of mineralization beneath the West Zone. This program consisted of five holes and all five holes intersected high grade gold, indicating strong continuation of mineralization at depth in the West Zone and warranting further exploration. The shallow West Zone infill drill program is ongoing. The results from the first two drill holes of the program are reported here, both of which intersected visible gold near surface.

Figure 2. Location of the West Zone drilling. Left image: Plan view image showing the West Zone target area in relation to Tuvatu, with underground developments shown in red and mineralized lodes in grey. Right image: view of the West Zone lodes and drilling looking east, with underground developments at Tuvatu shown in pale red in the background.

Table 1. Highlights of composited drill results in the West Zone area. Composites are calculated using a 3 g/t Au cutoff with maximum internal dilution intervals of 1 m at <3 g/t Au. For full results see Table 3 in the appendix.

|

Hole ID |

|

From (m) |

To (m) |

Width (m) |

Au (g/t) |

|---|---|---|---|---|---|

|

TUDDH-636 |

|

67.8 |

69.9 |

2.1 |

105.20 |

|

|

including |

67.8 |

68.4 |

0.6 |

72.55 |

|

|

and |

68.4 |

68.7 |

0.3 |

126.37 |

|

|

and |

68.7 |

69.0 |

0.3 |

248.35 |

|

|

and |

69.0 |

69.6 |

0.6 |

73.82 |

|

|

and |

69.6 |

69.9 |

0.3 |

68.96 |

|

TUDDH-647 |

|

144.5 |

146.6 |

2.1 |

70.07 |

|

|

including |

144.5 |

145.7 |

1.2 |

73.43 |

|

|

and |

145.7 |

146.6 |

0.9 |

65.58 |

|

TUDDH-645 |

|

97.7 |

98.9 |

1.2 |

102.38 |

|

TUDDH-636 |

|

34.5 |

39.6 |

5.1 |

19.82 |

|

|

including |

37.8 |

39.6 |

1.8 |

39.86 |

|

|

which includes |

38.7 |

39.6 |

0.9 |

68.88 |

|

TUDDH-645 |

|

164.3 |

164.9 |

0.6 |

146.61 |

|

|

including |

164.6 |

164.9 |

0.3 |

289.85 |

|

TUDDH-652 |

|

173.5 |

176.8 |

3.3 |

24.16 |

|

|

including |

173.5 |

175.3 |

1.8 |

37.08 |

|

|

which includes |

173.8 |

174.1 |

0.3 |

96.78 |

|

|

and also including |

176.2 |

176.5 |

0.3 |

33.37 |

|

TUDDH-636 |

|

60.6 |

62.4 |

1.8 |

42.44 |

|

|

including |

60.6 |

61.8 |

1.2 |

55.81 |

|

|

which includes |

60.6 |

61.2 |

0.6 |

61.66 |

|

|

and |

61.2 |

61.8 |

0.6 |

49.96 |

|

TUDDH-755 |

|

52.9 |

53.7 |

0.8 |

49.72 |

|

|

including |

52.9 |

53.3 |

0.4 |

78.61 |

|

TUDDH-645 |

|

142.4 |

146.6 |

4.2 |

7.68 |

|

|

including |

142.4 |

143.0 |

0.6 |

13.02 |

|

|

and |

144.2 |

144.8 |

0.6 |

19.76 |

|

TUDDH-636 |

|

228.8 |

230.8 |

2.0 |

14.86 |

|

TUDDH-642 |

|

179.1 |

182.1 |

3.0 |

8.23 |

|

TUDDH-642 |

|

172.5 |

175.5 |

3.0 |

6.44 |

|

|

including |

174.6 |

175.5 |

0.9 |

15.55 |

|

TUDDH-647 |

|

137.6 |

140.9 |

3.3 |

5.49 |

|

|

including |

140.0 |

140.9 |

0.9 |

12.89 |

|

TUDDH-753 |

|

57.6 |

58.3 |

0.7 |

25.22 |

|

|

including |

57.6 |

57.9 |

0.4 |

43.58 |

*All drill intersects are downhole lengths

The West Zone is located approximately 300 m to the west of the main Tuvatu deposit. It is modelled as a series of mainly east-west oriented lodes dipping steeply to the south. High grade gold has been sampled at surface in the West Zone and the area is coincident with a steeply dipping CSAMT gradient, indicative of a potential deep feeder structure in the area. Given the steeply dipping nature of the mineralized lodes both at Tuvatu and at the West Zone, and given the horizontal distance between the two systems, it is unlikely that they are fed by the same feeder zone. It is therefore hypothesized that there is a second feeder zone located at depth below the West Zone, which would be separate and distinct from the very high-grade Zone 500 feeder zone at Tuvatu.

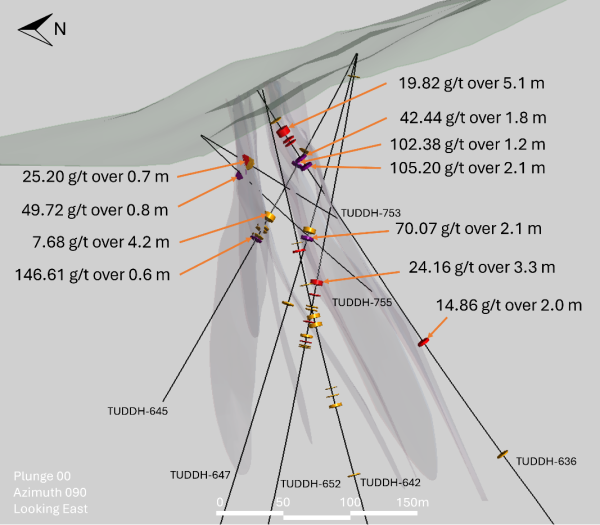

The deep drillholes reported in this news release are the first drillholes ever designed to test for feeder structures beneath the West Zone. Five drillholes were completed as part of this drill program (TUDDH-636, TUDDH-642, TUDDH-645, TUDDH-647, and TUDDH-652) and all five of these drillholes intersected high grade gold, including the headline intersections of 105.20 g/t Au over 2.1 m, 70.07 g/t Au over 2.1 m and 102.38 g/t Au over 1.2 m. These results indicate a strong potential for high-grade mineralization to continue further at depth below the West Zone and warrants additional exploration at depth. The deepest high-grade gold intersection returned in these first five drill holes was at almost 500 m depth downhole, with TUDDH-636 returning gold grades of 5.68 g/t and 7.00 g/t over 30 cm at 487.1 m and 482.0 m depth downhole respectively.

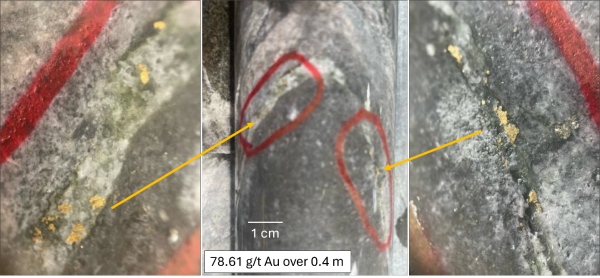

Structural analysis of oriented core and mapping of surface trenches in the West Zone has revealed the potential for north-south oriented mineralized structures as well as east-west oriented structures in the area. Historical drilling in the West Zone, however, has typically been oriented north-south to specifically target east-west oriented structures. This historical drilling is therefore likely to have missed any north-south oriented lodes as they would be oriented parallel to the drill direction. The infill drill program currently ongoing at the West Zone has been designed to intersect both the east-west and north-south oriented structures in this area by drilling in an oblique, northwest-southeast orientation. The first two holes of this drill program (TUDDH-753 and TUDDH-755) are reported in this news release. Both holes returned visible gold near surface (Figure 4).

Figure 3. West Zone drilling with high-grade intersects highlighted, 3.0 g/t gold cutoff. View is to the East. High to very high-grade gold is intersected near surface in the West Zone.

Figure 4. Visible gold from West Zone near surface drilling. Visible gold observed within narrow chalcedonic quartz roscoelite vein (TUDDH-755, from 52.9 m to 53.3 m). Left and right images are close-up views of visible gold seen in the center image.

The West Zone is not included in the current Tuvatu mine plan. However, given the high-grade mineralization present at surface in the West Zone as well as the close proximity of the West Zone to the Tuvatu processing plant, the West Zone is an ideal target for near-mine expansion. The West Zone is located just south of the mine office building at Tuvatu (Figure 5). To bring the West Zone into the current mine plan a second portal could be opened to provide direct access to the area, or an underground access drive could be developed from Tuvatu. The ongoing West Zone infill drill program is designed to help inform this decision as well as to increase confidence in the near-surface mineralization present in the West Zone.

Figure 5. Approximate location of the West Zone target area in relation to the Tuvatu processing plant and infrastructure.

Competent Persons Statement

The information in this report that relates to mineral exploration at the Tuvatu Gold Project is based on information compiled by the Lion One team and reviewed by Melvyn Levrel, who is the company’s Senior Geologist. Mr Levrel is a Member of the Australian Institute of Geoscientists and has sufficient experience that is relevant to the style of mineralisation and type of deposit under consideration, and to the activity being undertaken, to qualify as a Competent Person as defined in the 2012 edition of the ‘Australasian Code for Reporting of Exploration Results, Mineral Resources and Ore Reserves’ (JORC code). Mr Levrel consents to the inclusion in this report of the matters based on the information in the form and context in which it appears.

Lion One Laboratories / QAQC

Lion One adheres to rigorous QAQC procedures above and beyond basic regulatory guidelines in conducting its drilling, sampling, testing, and analyses. The Company operates its own geochemical assay laboratory and its own fleet of diamond drill rigs using PQ, HQ and NQ sized drill rods.

Diamond drill core samples are logged and split by Lion One personnel on site and delivered to the Lion One Laboratory for preparation and analysis. All samples are pulverized at the Lion One lab to 85% passing through 75 microns and gold analysis is carried out using fire assay with an AA finish. Samples that return grades greater than 10.00 g/t Au are re-analyzed by gravimetric method, which is considered more accurate for very high-grade samples.

Duplicates of 5% of samples with grades above 0.5 g/t Au are delivered to ALS Global Laboratories in Australia for check assay determinations using the same methods (Au-AA26 and Au-GRA22 where applicable). ALS also analyses 33 pathfinder elements by HF-HNO3-HClO4 acid digestion, HCl leach and ICP-AES (method ME-ICP61). The Lion One lab can test a range of up to 71 elements through Inductively Coupled Plasma Optical Emission Spectrometry (ICP-OES), but currently focuses on a suite of 23 important pathfinder elements with an aqua regia digest and ICP-OES finish.

About Lion One Metals Limited

Lion One Metals is an emerging Canadian gold producer headquartered in North Vancouver BC, with new operations established in late 2023 at its 100% owned Tuvatu Alkaline Gold Project in Fiji. The Tuvatu project comprises the high-grade Tuvatu Alkaline Gold Deposit, the Underground Gold Mine, the Pilot Plant, and the Assay Lab. The Company also has an extensive exploration license covering the entire Navilawa Caldera, which is host to multiple mineralized zones and highly prospective exploration targets.

On behalf of the Board of Directors,

Walter Berukoff, Chairman & CEO

Contact Information

Email: info@liononemetals.com

Phone: 1-855-805-1250 (toll free North America)

Website: www.liononemetals.com

Neither the TSX-V nor its Regulation Service Provider accepts responsibility or the adequacy or accuracy of this release

This press release may contain statements that may be deemed to be "forward-looking statements" within the meaning of applicable Canadian securities legislation. All statements, other than statements of historical fact, included herein are forward-looking information. Generally, forward-looking information may be identified by the use of forward-looking terminology such as "plans", "expects" or "does not expect", "proposed", "is expected", "budget", "scheduled", "estimates", "forecasts", "intends", "anticipates" or "does not anticipate", or "believes", or variations of such words and phrases, or by the use of words or phrases which state that certain actions, events or results may, could, would, or might occur or be achieved. This forward-looking information reflects Lion One Metals Limited’s current beliefs and is based on information currently available to Lion One Metals Limited and on assumptions Lion One Metals Limited believes are reasonable. These assumptions include, but are not limited to, the actual results of exploration projects being equivalent to or better than estimated results in technical reports, assessment reports, and other geological reports or prior exploration results. Forward-looking information is subject to known and unknown risks, uncertainties and other factors that may cause the actual results, level of activity, performance, or achievements of Lion One Metals Limited or its subsidiaries to be materially different from those expressed or implied by such forward-looking information. Such risks and other factors may include, but are not limited to: the stage development of Lion One Metals Limited, general business, economic, competitive, political and social uncertainties; the actual results of current research and development or operational activities; competition; uncertainty as to patent applications and intellectual property rights; product liability and lack of insurance; delay or failure to receive board or regulatory approvals; changes in legislation, including environmental legislation, affecting mining, timing and availability of external financing on acceptable terms; not realizing on the potential benefits of technology; conclusions of economic evaluations; and lack of qualified, skilled labor or loss of key individuals. Although Lion One Metals Limited has attempted to identify important factors that could cause actual results to differ materially from those contained in forward-looking information, there may be other factors that cause results not to be as anticipated, estimated, or intended. Accordingly, readers should not place undue reliance on forward-looking information. Lion One Metals Limited does not undertake to update any forward-looking information, except in accordance with applicable securities laws.

Appendix 1: Full Drill Results and Collar Information

Table 2. Collar coordinates for drillholes reported in this release. Coordinates are in Fiji map grid.

|

Hole ID |

Easting |

Northing |

Elevation |

Azimuth |

Dip |

Depth |

|---|---|---|---|---|---|---|

|

TUDDH-636 |

1875867 |

3920760 |

175 |

160.0 |

-56.8 |

515.8 |

|

TUDDH-642 |

1875885 |

3920756 |

175 |

186.4 |

-76.4 |

417.0 |

|

TUDDH-645 |

1875917 |

3920685 |

203 |

325.9 |

-59.5 |

311.9 |

|

TUDDH-647 |

1875917 |

3920685 |

203 |

326.0 |

-72.2 |

458.3 |

|

TUDDH-652 |

1875918 |

3920685 |

203 |

325.0 |

-79.1 |

783.0 |

|

TUDDH-753 |

1875838 |

3920802 |

141 |

125.8 |

-19.6 |

184.9 |

|

TUDDH-755 |

1875838 |

3920802 |

141 |

131.8 |

-33.4 |

220.4 |

Table 3. Composite results from drillholes reported in this news release (composite grade >3.0 g/t Au)

| Hole ID | From (m) | To (m) | Width (m) | Au (g/t) | |

|---|---|---|---|---|---|

| TUDDH-636 | 26.7 | 27.3 | 0.6 | 6.28 | |

| TUDDH-636 | 34.5 | 39.6 | 5.1 | 19.82 | |

| including | 34.5 | 35.1 | 0.6 | 3.657 | |

| and | 35.1 | 35.7 | 0.6 | 15.96 | |

| and | 35.7 | 36.3 | 0.6 | 18.29 | |

| and | 36.3 | 36.9 | 0.6 | 10.99 | |

| and | 36.9 | 37.8 | 0.9 | 0.01 | |

| and | 37.8 | 38.7 | 0.9 | 10.84 | |

| and | 38.7 | 39.6 | 0.9 | 68.88 | |

| TUDDH-636 | 43.8 | 44.7 | 0.9 | 11.22 | |

| including | 43.8 | 44.4 | 0.6 | 13.59 | |

| and | 44.4 | 44.7 | 0.3 | 6.47 | |

| TUDDH-636 | 47.1 | 47.7 | 0.6 | 12.23 | |

| TUDDH-636 | 60.6 | 62.4 | 1.8 | 42.44 | |

| including | 60.6 | 61.2 | 0.6 | 61.66 | |

| and | 61.2 | 61.8 | 0.6 | 49.96 | |

| and | 61.8 | 62.4 | 0.6 | 15.69 | |

| TUDDH-636 | 67.8 | 69.9 | 2.1 | 105.2 | |

| including | 67.8 | 68.4 | 0.6 | 72.55 | |

| and | 68.4 | 68.7 | 0.3 | 126.37 | |

| and | 68.7 | 69 | 0.3 | 248.35 | |

| and | 69 | 69.6 | 0.6 | 73.82 | |

| and | 69.6 | 69.9 | 0.3 | 68.96 | |

| TUDDH-636 | 228.8 | 230.8 | 2 | 14.86 | |

| TUDDH-636 | 334.2 | 335.1 | 0.9 | 4.86 | |

| TUDDH-636 | 429.8 | 430.1 | 0.3 | 3.06 | |

| TUDDH-636 | 472.1 | 473 | 0.9 | 3.55 | |

| TUDDH-636 | 482 | 482.3 | 0.3 | 7 | |

| TUDDH-636 | 487.1 | 487.4 | 0.3 | 5.68 | |

| TUDDH-642 | 117.6 | 117.9 | 0.3 | 8.1 | |

| TUDDH-642 | 123 | 124.5 | 1.5 | 10.23 | |

| including | 123 | 123.6 | 0.6 | 11.96 | |

| and | 123.6 | 124.5 | 0.9 | 9.08 | |

| TUDDH-642 | 149.4 | 150 | 0.6 | 5.28 | |

| TUDDH-642 | 172.5 | 175.5 | 3 | 6.44 | |

| including | 172.5 | 172.8 | 0.3 | 5.39 | |

| and | 172.8 | 173.7 | 0.9 | 4 | |

| and | 173.7 | 174.6 | 0.9 | 0.12 | |

| and | 174.6 | 175.5 | 0.9 | 15.55 | |

| TUDDH-642 | 179.1 | 182.1 | 3 | 8.23 | |

| including | 179.1 | 180 | 0.9 | 8.68 | |

| and | 180 | 180.3 | 0.3 | 12.64 | |

| and | 180.3 | 180.6 | 0.3 | 10.99 | |

| and | 180.6 | 181.2 | 0.6 | 8.91 | |

| and | 181.2 | 182.1 | 0.9 | 4.95 | |

| TUDDH-642 | 229.2 | 229.5 | 0.3 | 4.21 | |

| TUDDH-642 | 234.9 | 235.5 | 0.6 | 5.82 | |

| including | 234.9 | 235.2 | 0.3 | 7.02 | |

| and | 235.2 | 235.5 | 0.3 | 4.62 | |

| TUDDH-642 | 241.8 | 243.9 | 2.1 | 8.1 | |

| including | 241.8 | 242.4 | 0.6 | 11.23 | |

| and | 242.4 | 243.3 | 0.9 | 0.93 | |

| and | 243.3 | 243.6 | 0.3 | 10.55 | |

| and | 243.6 | 243.9 | 0.3 | 20.86 | |

| TUDDH-642 | 296.3 | 297.2 | 0.9 | 3.52 | |

| TUDDH-642 | 323 | 323.6 | 0.6 | 7.35 | |

| TUDDH-645 | 86 | 86.3 | 0.3 | 4.91 | |

| TUDDH-645 | 97.7 | 98.9 | 1.2 | 102.38 | |

| TUDDH-645 | 142.4 | 146.6 | 4.2 | 7.68 | |

| including | 142.4 | 143 | 0.6 | 13.02 | |

| and | 143 | 143.3 | 0.3 | 9.81 | |

| and | 143.3 | 143.6 | 0.3 | 5.8 | |

| and | 143.6 | 143.9 | 0.3 | -0.01 | |

| and | 143.9 | 144.2 | 0.3 | 8.14 | |

| and | 144.2 | 144.5 | 0.3 | 10.88 | |

| and | 144.5 | 144.8 | 0.3 | 28.63 | |

| and | 144.8 | 145.4 | 0.6 | 1.3 | |

| and | 145.4 | 146 | 0.6 | 3.97 | |

| and | 146 | 146.6 | 0.6 | 3.85 | |

| TUDDH-645 | 152.9 | 154.1 | 1.2 | 4.77 | |

| including | 152.9 | 153.2 | 0.3 | 8.38 | |

| and | 153.2 | 153.5 | 0.3 | 1.51 | |

| and | 153.5 | 154.1 | 0.6 | 4.6 | |

| TUDDH-645 | 155.9 | 156.5 | 0.6 | 7.88 | |

| TUDDH-645 | 161.6 | 162.2 | 0.6 | 9.46 | |

| TUDDH-645 | 164.3 | 164.9 | 0.6 | 146.61 | |

| including | 164.3 | 164.6 | 0.3 | 3.36 | |

| and | 164.6 | 164.9 | 0.3 | 289.85 | |

| TUDDH-647 | 137.6 | 140.9 | 3.3 | 5.49 | |

| including | 137.6 | 138.2 | 0.6 | 5.39 | |

| and | 138.2 | 139.1 | 0.9 | <0.01 | |

| and | 139.1 | 140 | 0.9 | 3.66 | |

| and | 140 | 140.9 | 0.9 | 12.89 | |

| TUDDH-647 | 144.5 | 146.6 | 2.1 | 70.07 | |

| including | 144.5 | 145.7 | 1.2 | 73.43 | |

| and | 145.7 | 146.6 | 0.9 | 65.58 | |

| TUDDH-647 | 196.7 | 197.6 | 0.9 | 5.13 | |

| including | 196.7 | 197 | 0.3 | 6.46 | |

| and | 197 | 197.3 | 0.3 | 4.85 | |

| and | 197.3 | 197.6 | 0.3 | 4.07 | |

| TUDDH-652 | 17.6 | 17.9 | 0.3 | 4.96 | |

| TUDDH-652 | 173.5 | 176.8 | 3.3 | 24.16 | |

| including | 173.5 | 173.8 | 0.3 | 29.86 | |

| and | 173.8 | 174.1 | 0.3 | 96.78 | |

| and | 174.1 | 174.4 | 0.3 | 20.89 | |

| and | 174.4 | 174.7 | 0.3 | 38.19 | |

| and | 174.7 | 175 | 0.3 | 15.99 | |

| and | 175 | 175.3 | 0.3 | 20.75 | |

| and | 175.3 | 175.6 | 0.3 | 0.4 | |

| and | 175.6 | 175.9 | 0.3 | 1.8 | |

| and | 175.9 | 176.2 | 0.3 | 2.28 | |

| and | 176.2 | 176.5 | 0.3 | 33.37 | |

| and | 176.5 | 176.8 | 0.3 | 5.41 | |

| TUDDH-652 | 184.3 | 184.9 | 0.6 | 15.26 | |

| TUDDH-652 | 193.3 | 193.9 | 0.6 | 7.71 | |

| TUDDH-652 | 195.7 | 196.3 | 0.6 | 5.29 | |

| including | 195.7 | 196 | 0.3 | 5.03 | |

| and | 196 | 196.3 | 0.3 | 5.55 | |

| TUDDH-652 | 205 | 205.6 | 0.6 | 12.65 | |

| including | 205 | 205.3 | 0.3 | 9.33 | |

| and | 205.3 | 205.6 | 0.3 | 15.96 | |

| TUDDH-652 | 215.2 | 217 | 1.8 | 6.32 | |

| including | 215.2 | 215.5 | 0.3 | 5.45 | |

| and | 215.5 | 215.8 | 0.3 | 1.34 | |

| and | 215.8 | 216.1 | 0.3 | 4.56 | |

| and | 216.1 | 216.4 | 0.3 | 7.43 | |

| and | 216.4 | 216.7 | 0.3 | 3.3 | |

| and | 216.7 | 217 | 0.3 | 15.82 | |

| TUDDH-652 | 220.3 | 220.6 | 0.3 | 26.72 | |

| TUDDH-652 | 223.3 | 223.6 | 0.3 | 3.56 | |

| TUDDH-652 | 224.5 | 224.8 | 0.3 | 4.13 | |

| TUDDH-652 | 430.2 | 431.4 | 1.2 | 3.9 | |

| including | 430.2 | 430.8 | 0.6 | 3.99 | |

| and | 430.8 | 431.4 | 0.6 | 3.8 | |

| TUDDH-753 | 57.6 | 58.3 | 0.7 | 25.22 | |

| including | 57.6 | 57.9 | 0.4 | 43.58 | |

| and | 57.9 | 58.3 | 0.4 | 6.86 | |

| TUDDH-753 | 60.5 | 60.9 | 0.5 | 7.94 | |

| TUDDH-753 | 64.4 | 65.2 | 0.8 | 4.4 | |

| including | 64.4 | 64.7 | 0.3 | 5.58 | |

| and | 64.7 | 65.2 | 0.5 | 3.69 | |

| TUDDH-755 | 52.9 | 53.7 | 0.8 | 49.72 | |

| including | 52.9 | 53.3 | 0.4 | 78.61 | |

| and | 53.3 | 53.7 | 0.4 | 21.56 | |

| TUDDH-755 | 64.7 | 65 | 0.3 | 6.2 | |

| TUDDH-755 | 68.2 | 68.5 | 0.3 | 2 | |

| TUDDH-755 | 153.6 | 153.9 | 0.3 | 2.19 | |

| *All drill intersects are downhole lengths | |||||